Design Features

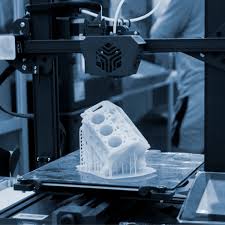

Contains software and hardware components. This includes 3D-printed mounts, stepper motors, movable stage, and automated image capturing with corresponding analysis

Learn more

Currently, trained technicians manually inspect filters or metal particles after flushing Alcon’s Active Sentry Handpieces. As demands grow, this manual process becomes time-consuming, inconsistent, and hard to scale. We are developing a fully automated particle counting system using high-resolution optics, custom hardware, and AI-powered image analysis. Our systems reduces manual labor, increases throughput, and enhances precision, all while maintaining compliance with medical device standards.

Our system automates particulate detection during the final quality testing stage for surgical handpieces. By combining motorized precision, high-definition imaging, and intelligent analysis, we reduce manual labor and increase throughput.

Contains software and hardware components. This includes 3D-printed mounts, stepper motors, movable stage, and automated image capturing with corresponding analysis

Learn more

Alcon enables access to technicians performing this quality control process, we aim to perfect the automation to meet all of the manual work done by the technicians. Constant reiteration is performed until 100% accuracy in particle detection is achieved.

Learn more

Most of our components are bought or 3D printed for prototyping, meaning that materials vary a lot, the prepared material for these parts would be nylon is it has improved manufactuing precision.

Learn more