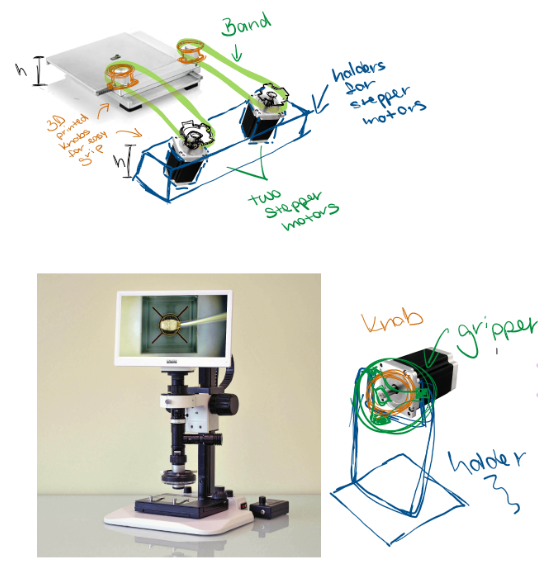

Pulley System Stage Controller

The movement mechanism consists of rubber bands connecting to the knobs and the stepper motors.

Learn how we brainstormed, protoype, and manufactured our product.

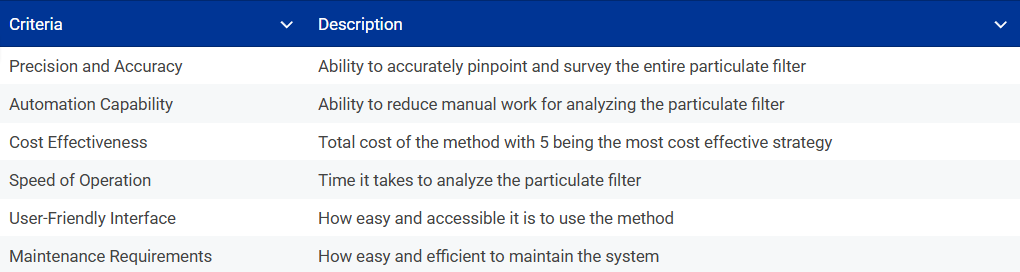

The constant testing re-iteration of the hardware components finally yields the current design, “Alcount.” The design consists of stepper motors directly connected to the origin of the x and y movement to guarantee coverage of the entire sample slide. We also implemented the slide holder and railings to guarantee easy removal of each slide holder. The current design coupled with the “YOLO” image processing software allowed the quality control process to be automated.

The constant testing re-iteration of the hardware components finally yields the current design, “Alcount.” The design consists of stepper motors directly connected to the origin of the x and y movement to guarantee coverage of the entire sample slide. We also implemented the slide holder and railings to guarantee easy removal of each slide holder. The current design coupled with the “YOLO” image processing software allowed the quality control process to be automated.

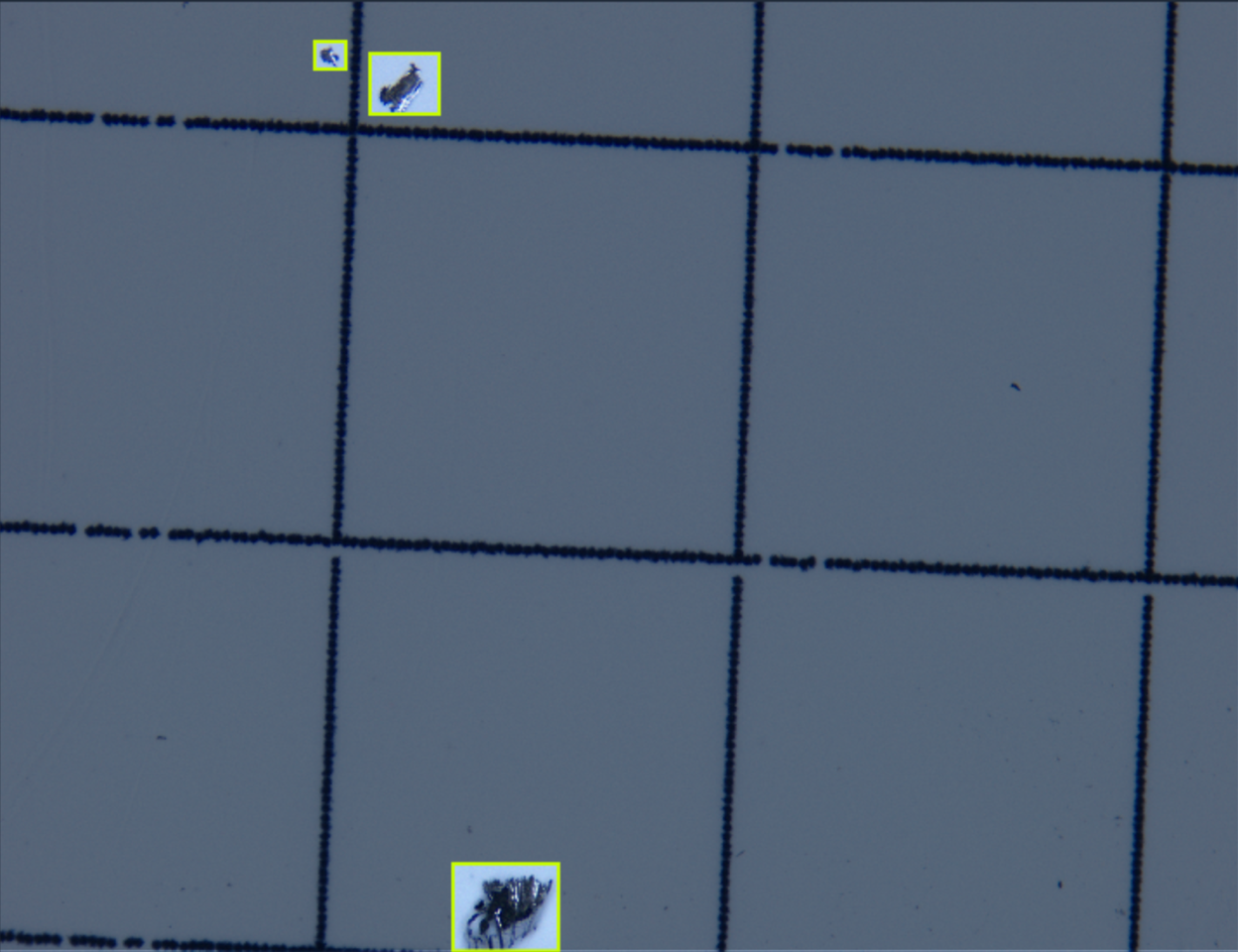

the image processing software we are utilizing to detect titanium particles and measure them in order to record it and run it through a pass/fail system. We define a threshold at which each slide has to be processed, if the software detects a slide content exceeding this set threshold, the handpiece will fail the quality control and be discarded.

the image processing software we are utilizing to detect titanium particles and measure them in order to record it and run it through a pass/fail system. We define a threshold at which each slide has to be processed, if the software detects a slide content exceeding this set threshold, the handpiece will fail the quality control and be discarded.